Ammonia skid removal system

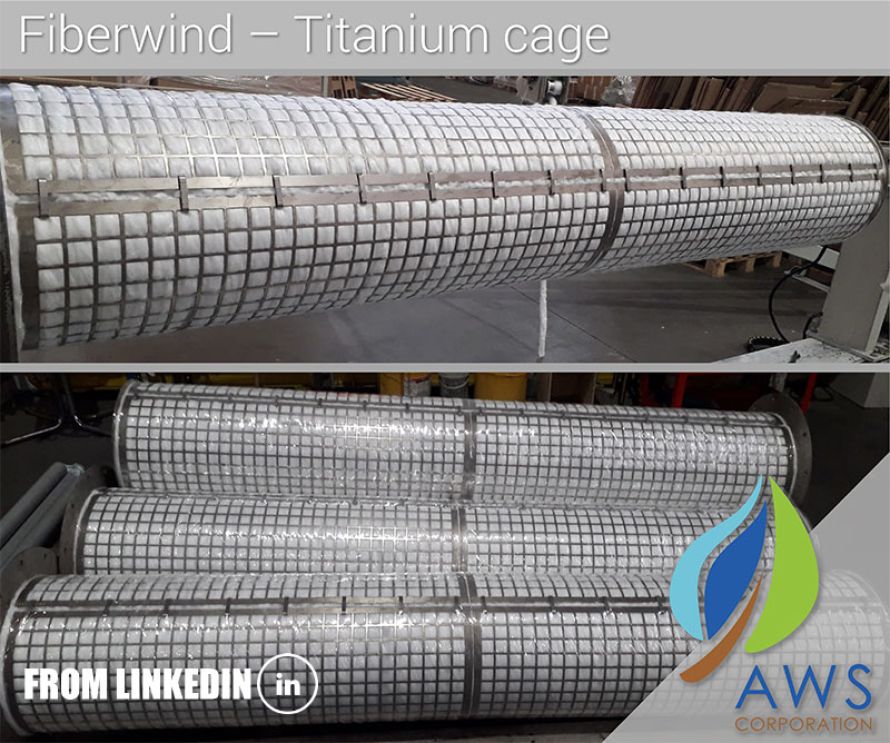

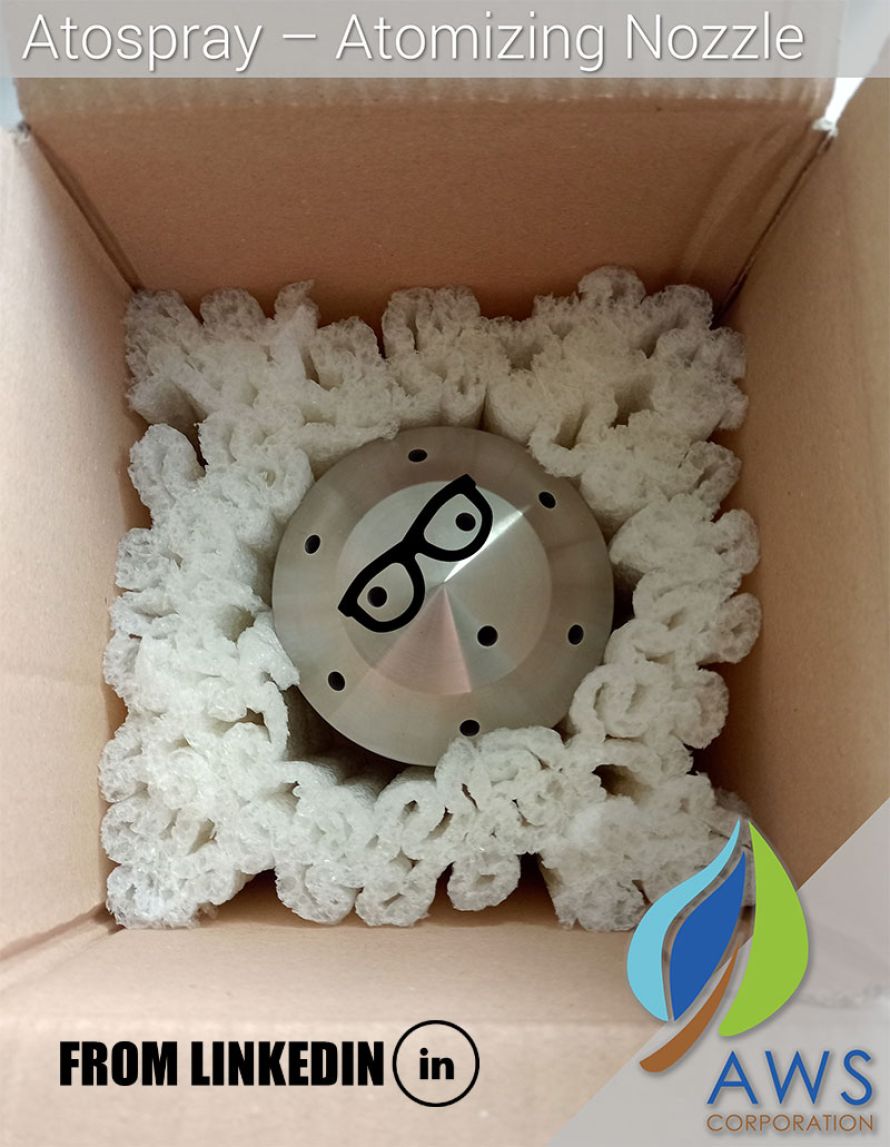

Here you can see a member of our Atospray family:Ammonia removal system complete of dosing system + a full set of lances and nozzles. This skid will be installed in a waste-to-energy plant, based in Italy.