Oil Mist Separator

LOV™ MIST SEPARATOR

AWS can contribute to the solution of many pollution control problems caused by oil mist. The lubricated rotating parts of all gas and steam turbines, turbo compressors and vacuum pumps generate a visible oil plume which is to be removed from the air vented to atmosphere. The installation of a simple but very effective mist eliminator on the lube oil vent solves the pollution problem and, by recovering the expensive oil, pays off the mist eliminator cost in a short period of time.

AWS LOV mist eliminator system is our technology option developed to provide turbines & compressor manufacturers with a choice of solutions to address the main regulatory requirements .

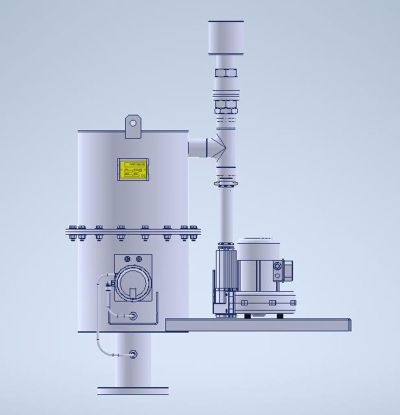

LOV mist eliminator is a modular lube oil mist eliminator system, providing a safe, flexible and economical process for the treatment of lube oil mist. Lube oil mist treatment with a LOV AWS system is achieved through a simple and efficient one stage process. The lube oil mist passes through a brownian movement candle filter with special fiber that collects oil mist particles.

Standard Features

The core part of our filter is the special inert glass fiber which is densely packed inside two concentric metal screens.

The peculiarity of the fibers and their specific density are responsible for a removal efficiency of up to 99.99% for all particles down to 0.1 micron.

Measurements made on installed mist eliminators have demonstrated residual oil mist contents far below 5 mg/m3 in the air being vented to atmosphere.

On top of the extremely high efficiency, AWS mist eliminator combines a very low pressure drop that remains costant during the time, plus a maintenance-free operating system that will last for years. The collected oil mist is continuously discharged from the filter and recirculated back to the lube oil tank.

The pressure drop of the coalescing mist eliminator of AWS is very low, usually in the range of a few mbar which can avoid the installation of a sucking blower downstream of the mist eliminator.

Virtually, the mist eliminator can be sized to achieve a very minimum pressure drop according to customer’s request. The lower the requested pressure drop requirements, the larger will be the installed coalescing area.

Equipment supply and installation

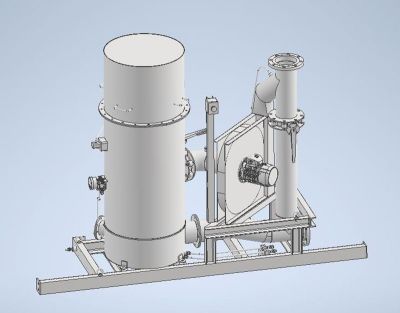

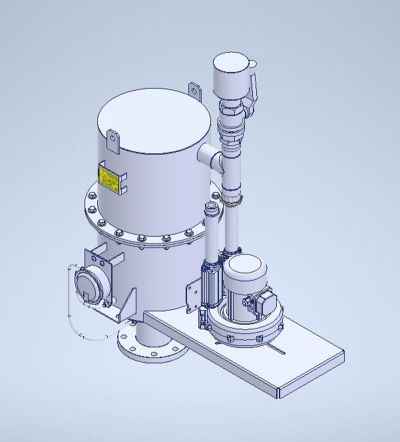

AWS can supply the simple mist eliminator or, according to customer’s requirements, a skid mounted unit which includes by-pass pipe, control valves, instrumentation, blower and motor.

For installations where room availability is a problem, AWS can provide tailor made solutions.

Main advantages

- Broad environmental operating principle

- Flexible configuration

- Low maintenance and operating costs

- High efficiency removal with constant performances

- Modular construction for

- Efficient use of space and power

- Easy integration with turbines/compressors systems

- Flexible up-scaling